BACK

BACK

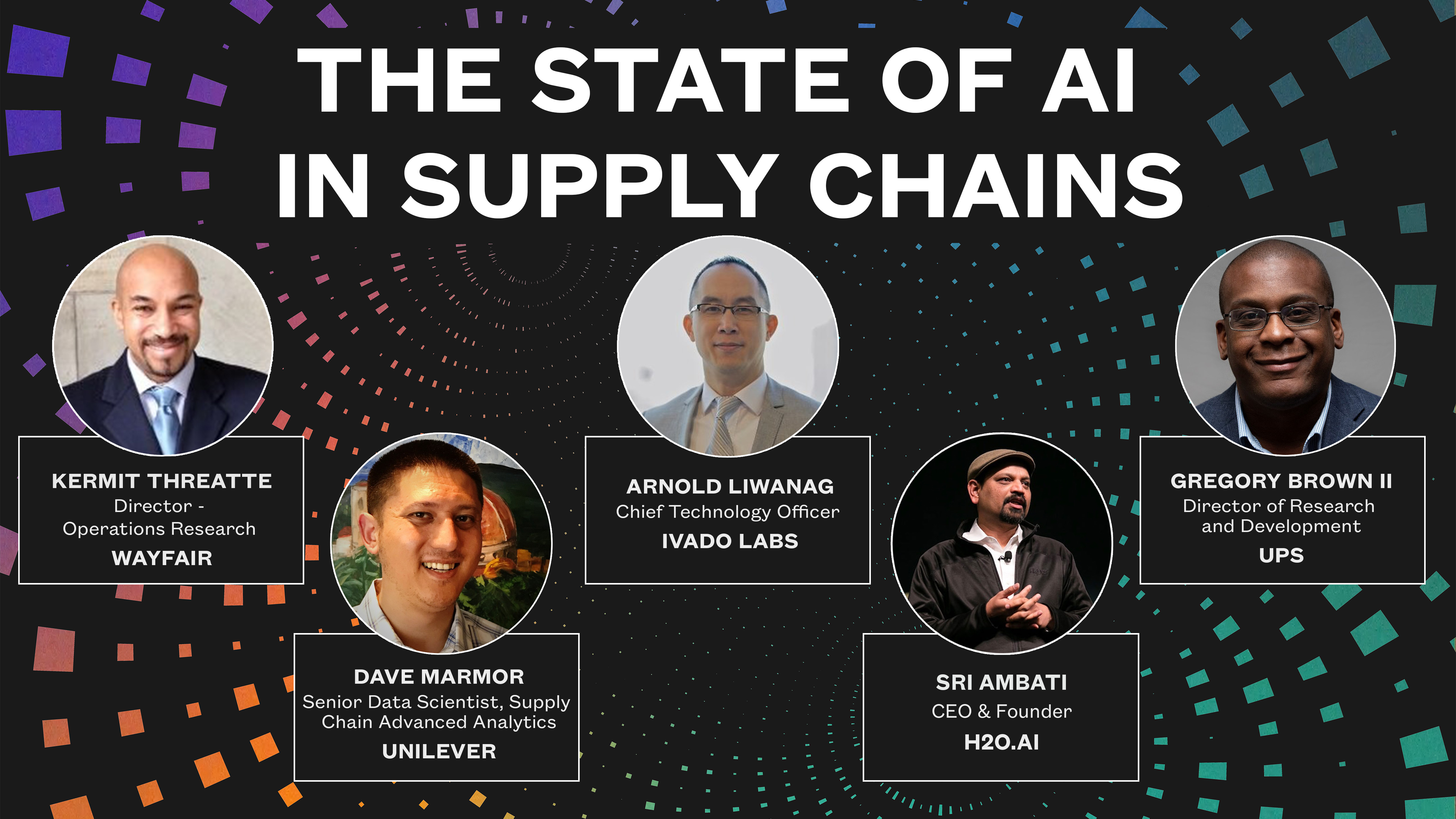

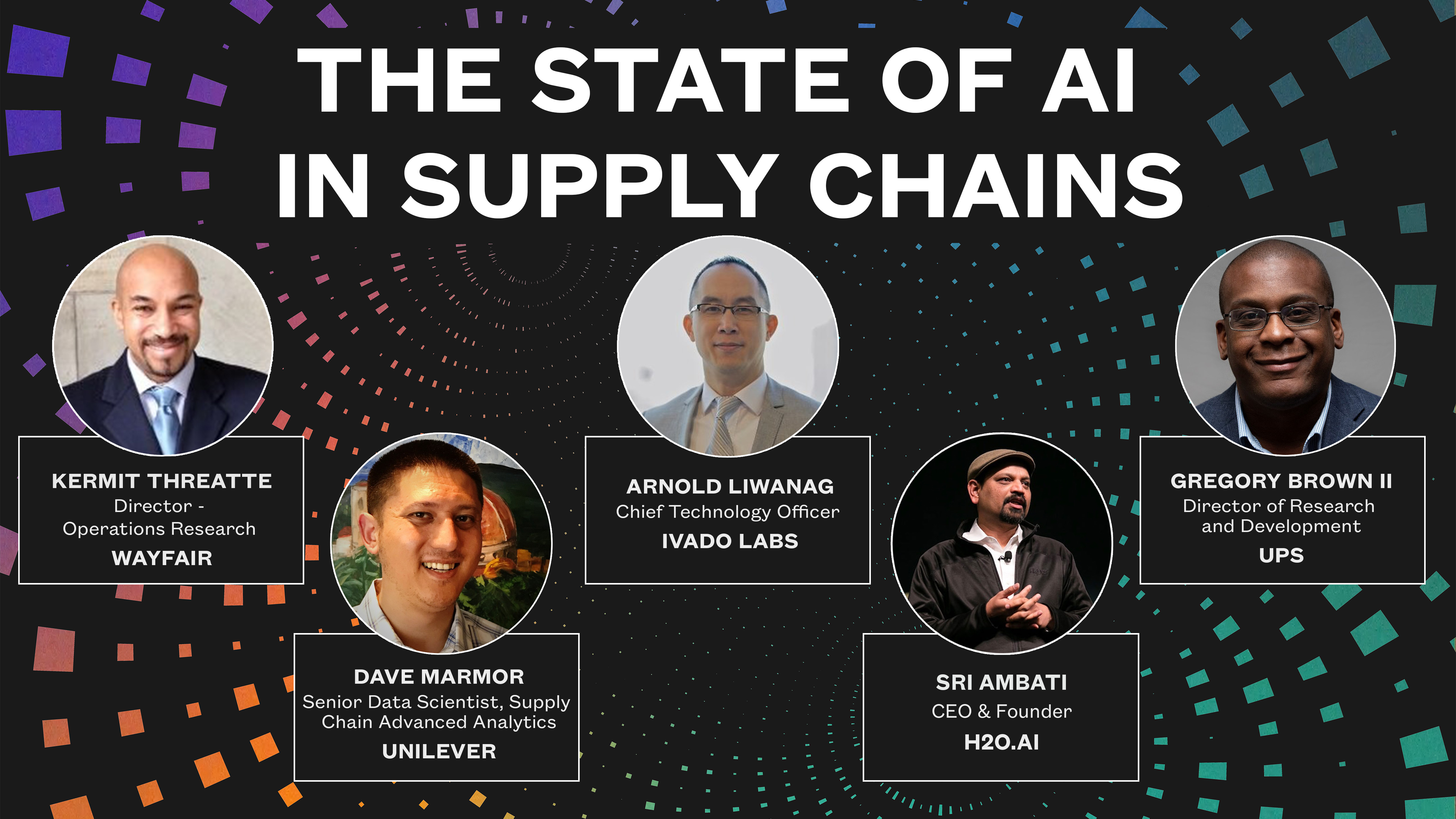

During this panel, industry experts (showed above) discussed the impact of COVID-19 on AI on Supply Chains. We’ve included a short transcription of the panel, beginning at 28:40 of the webinar.

Kermit Threatte, Wayfair: What are some of the biggest bottlenecks in our supply chains and how is AI helping?

David Marmor, Unilever: Yeah. I think what we're finding out is that a lot of the work that's done in the supply chain is actually done quite manually as opposed to autonomous. In the futuristic kind of state that we envision everything is at and we're really not quite there yet. We have a lot of legacy systems; I think this is true for mostly every company. There's a lot of getting on the phone and calling up carriers when you need to. A lot of this has not been fully automated and I think when you suddenly have a situation where it was so clear how many orders we need to get in in such a limited period of time that a lot of the manual work on this cannot be done that fast.

We're starting to see areas that normally would not ask for additional help in automating certain tasks because it's not that they think a computer can't do what they do, it's that it's just never been quite an issue but now it is suddenly changed where there's just too much volume for them to be able to handle and so our team has been getting a lot of requests to automate this and automate that -- whether it's with ordering or with inventory management.

Kermit, you mentioned something earlier about in general all forecast models. I don't think I'm giving away any secrets here when I say our forecast models are using historical data. We're going to have a very tough time now looking at the past month of data, then figure out what our customers will be looking to order in the future. Basically what the big transition has been are tasks that were manual and the never was really a particularly big deal to automate something, whereas now automation is absolutely the utmost important.

Kermit Threatte, Wayfair: Yeah, and don't worry. You didn't give away any state secrets. Would anyone else like to elaborate?

Sri Ambati, H2O.ai: I think the choke points are around food and food safety. We've been working with a perishable distribution company - like it delivers blueberries across the nation and makes sure they're fresh and available locally without getting damaged. All of that takes a new set of algorithms, supply chain of perishables, and supply chain of staples and non-perishables.

How do we now make food local as well, so that you can spend less time on the road? How do you start making sure that things are safe while also accessible? These are the kinds of discussions that need a little bit more modeling than in the past.

David Marmor, Unilever: Well, we've seen some of our clients and the man side has dropped to zero - five percent of what it was - and then on the opposite side, demand is 200-300%. So that's what covid has done or exposed.

Kermit Threatte, Wayfair: If you look at the spare parts, somebody orders a thousand of one particular spare part, it might clean your supply chain out and you have to restock. Usually people don't need a thousand at once.

There's one big bottleneck which, in this environment, is probably worse because it hits the essential workers, but this even before Coronavirus. Throughout the supply chain industry, getting labor has always been challenging. Everybody who has actually been distributing products has their warehouses in the same places already. When you start doing the US, there's a place where you put your first warehouse there's always the same place to put your second and so on and so forth.

If you go to any of these warehouse centers, you'll see an Amazon warehouse, a Wayfair warehouse, you'll see a whole bunch of warehouses clustered in all trying to get the same labor. I find that that’s a decent bottleneck that most major supply chains are facing, at least in North America. Anything that can be done to try to make people more efficient at doing their jobs so that the labor demands go down which I think AI has a lot of ability to do is helpful.

Sri Ambati, H2O.ai: I think hospitals and staffing and predicting supply chains for hospitals, especially PP is difficult. I've been working closely with our partners in healthcare. Obviously, there is a first and foremost supply chain that got a spike in demand and choke points and bottlenecks there. This is a privilege to be in support of the front line and do whatever we can do to help them with the supply chain analytics. Predicting the number of ventilators needed to number beds and hospitals needed those have all been relatively similar types of problems that we've been looking at with our Partners in healthcare. But I think in general, the overall system has a high demand and no demand aspect to it.

Recent Posts

Developing Computer Vision Applications in Data Scarce Environments

Introduction In today’s digital era, computer vision stands as a transformative technology, driving innovations across...

By Sumedh DatarDecember 12, 2023

How COVID-19 is Impacting the State of AI in Supply Chains

During this panel, industry experts (showed above) discussed the impact of COVID-19 on AI on...

By Ai4May 04, 2020

“Ask Me Anything” with Zappos’s Head of AI/ML Research & Platforms, Ameen Kazerouni

Ai4 recently hosted an “Ask Me Anything” session with one of our speakers, Ameen Kazerouni,...

By Ai4March 19, 2020